- HOME>

- TAKING ON NEW CHALLENGES FOR NEW GROWTH>

- Building a Manufacturing and Supply System with Lightning-Fast Reactions

September 2012 will see the start-up of operations at Sammy's new plant and distribution center. We have invested roughly ¥13.5 billion* to build a new plant on a lot adjacent to our existing plant in Kawagoe, Saitama Prefecture. The new plant's floor area of approximately 36,000 square meters is about twice that of the existing plant. Furthermore, we have invested ¥2.7 billion* to build a new distribution center on land next to the new plant. The center will begin operating at the same time as the new plant.

Aiming for even higher earnings from the Pachislot and Pachinko Machine Business segment centered on the Sammy brand, the SEGA SAMMY Group will continue bolstering the pachislot machine business while pursuing the medium-term target of capturing a leading position in the pachinko machine market, where considerable leeway remains for growing market share. Sammy's new plant and distribution center will bring two major strategic benefi ts. First, it will dramatically steepen the growth trajectory of the pachinko machine business, which has established a stable market share of more than 10% in recent years and is heightening its presence steadily. Second, it will further strengthen the earnings structure of the Pachislot and Pachinko Machine Business segment, which is the Group's earnings driver.

The new plant's production line will enable the manufacture of a range of pachinko machines with diverse specifi cations and highly appealing staging. Generally, shipments peak in the initial period after launching pachislot and pachinko machines. For example, we receive more than 90% of orders for pachinko machines in our flagship Pachinko CR Hokuto No Ken series in the first week after launch. The operations of our new plant will give our manufacturing and supply system lightning-fast reactions, allowing us to cater to such intensive short-term demand and thereby avoid sales opportunity loss.

* Excluding the purchase of lots previously acquired

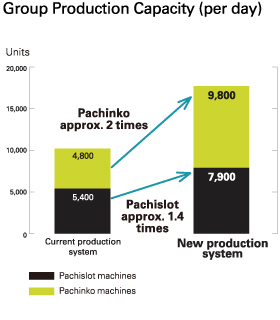

Sammy has been developing its manufacturing system for pachislot and pachinko machines at Kawagoe since its existing plant began operations there in 2001. By ramping up in stages, the plant has reached a total production capacity of 2,400 units per day for pachislot and pachinko machines. Regarding pachinko machines, however, the industry's leading companies have production capacities two or three times larger than Sammy's. Therefore, to erode the leading market shares of such competitors, Sammy needs more production capacity.

With this in mind, the new plant will boast a production capacity of 2,500 pachislot machines and 5,000 pachinko machines per day. This will give us lightning-fast reactions able to reliably meet initial demand for “killer” titles in such series as CR Hokuto No Ken and CR SOUTEN-NO-KEN. The existing plant's continuing operations, Group companies, and the new plant will be able to manufacture a combined total of 7,900 pachislot machines and 9,800 pachinko machines per day-one of the largest production capacities in the industry.

As well as increasing production capacity, to enable rapid responses to intensive short-term demand, we have introduced a variety of improved production processes to shorten production lead times. These initiatives include shortening in-house assembly times by outsourcing processes for attaching cells to boards and routing processes for putting holes in boards and systemizing process control to reduce man-hours while heightening the precision of processes.

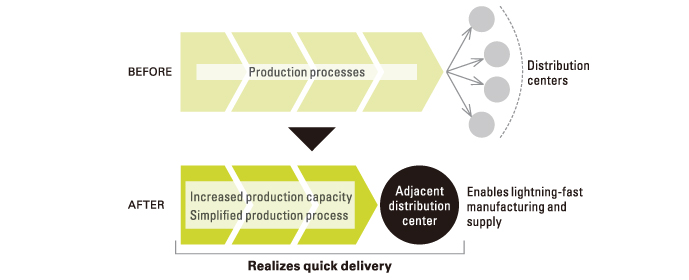

Until now, we have temporarily stored completed products at warehouses after they had gone through a series of production processes that includes board assembly, machining, circuit board assembly, and machine cabinet assembly. At these warehouses we conduct such operations as mounting boards and attaching certifi cation labels to products before shipping them to respective distribution centers. For the new plant, however, we will abolish product storage warehouses and change to a simplified format that integrates operations from receiving orders through to production and shipping. This will shorten our overall production process and increase the percentage of products manufactured and shipped on the same day significantly.

Combined with the increased production capacity realized through the new plant, the new distribution center will synergistically enable the lightning-fast reactions of our production and supply.

The new distribution center will bring together at a single location the capabilities of the largest of our four distribution centers in Japan, located in Tsurugashima, Saitama Prefecture, and component warehouses at six different locations. By consolidating product distribution, component storage, and reuse and recycling capabilities next to our production base, we will dramatically shorten lead times from production through to shipping. Moreover, the new distribution center will give us 2.5 times more storage capacity than before, establishing a fully prepared shipping system able to deal with initial surges in orders. Other benefi ts will include more effi cient reuse and recycling and lower transportation expenses to distribution centers.

Also, the new distribution center will incorporate an upgraded system for controlling warehousing, shipping, and delivery operations that improves operations by reducing man-hours and realizing real-time inventory recording.

Having almost completed one of the best manufacturing and supply systems for pachislot and pachinko machines in the industry, the SEGA SAMMY Group is poised to launch a full-fl edged drive to defend its top share of the pachislot machine market and to seize a much larger share of the pachinko machine market. We are looking forward to realizing signifi cant earnings benefi ts. For example, increased production capacity, combined with our ability to refl ect fl uctuations in order trends by changing production plans in real-time, will help reduce component disposal loss. We view the new plant and distribution center as the core strategic base of the Pachislot and Pachinko Machine Business segment. As such, we intend to exploit its capabilities to the utmost.