Focus

Focus8 | Sammy’s New Challenge “Recycled Material Circulation Scheme”

Established a system to make new Pachislot and Pachinko Machines from plastic parts of the retired Pachislot and Pachinko Machines

(Left)

Oyauchi Masaki

Sammy Corporation

Reuse Planning Group, Production Planning Department, Production Planning Division, Production Headquarters

(Right)

Inouchi Takaya

Sammy Corporation

Chief, Procurement Group 1, Procurement Department, Production Planning Division, Production Headquarters

* Interviewed in: December 2024

Sammy, responsible for the Pachislot and Pachinko Machines business within SEGA SAMMY Group, is taking the “environment,” one of the Group’s materiality issues, very seriously. For example, we have used environmentally friendly PEFC-certified lumber and have implemented the commoditization of components and minimization of parts that make up Pachislot and Pachinko Machines*1.

In 2024, a new initiative, the “Recycled Material Circulation Scheme,” was launched to again use the plastic from recovered and dismantled Pachislot and Pachinko Machines as raw materials. This circulation scheme was made possible through the proactive efforts from Sammy’s future generation, cooperating with related departments and suppliers.

What was the idea behind the circulation scheme? Also, what difficulties did they face in establishing the circulation scheme? This time, the struggles of the staff in the procurement and reuse sections, whose work is not usually known, will be introduced.

Roles and environmental awareness of procurement and reuse departments

Inouchi

The Procurement Department is responsible for selecting parts suppliers and coordinating delivery dates. Although we have been working on environmental measures for some time, we have been more conscious of our sustainability efforts since around 2021, when the term SDGs became widespread in society and was used in our department’s business action plan. Around that time, we began working closely with the Reuse Planning Group.。

Oyauchi

The Production Planning Department is responsible for creating production plans for how many Pachinko and Pachislot Machines to produce and when, as well as for managing the overall production progress. We have established the Reuse Planning Group and are working to reduce CO2 emissions and other environmental burdens within this group. For example, we reuse components commonly used in different models. Sometimes we are asked by the Procurement Department, “Can we reuse these parts?” and we investigate it.

What is the recycled material circulation scheme for Pachislot and Pachinko Machines?

This time, we will introduce a circulation scheme for polycarbonate (a type of plastic) parts mainly used as decorations for the main body of Pachislot and Pachinko Machines.

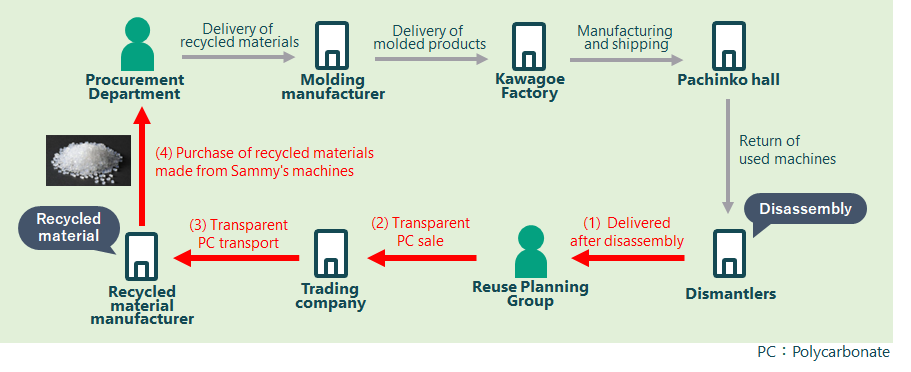

For some time now, Sammy has used not only new raw materials in producing plastic parts but also recycled raw materials purchased from recycled material manufacturers. To that existing scheme, we have added a procedure for selling dismantled Sammy machines to a trading company for delivery to a recycled material manufacturer ((1) to (3) in the figure) and a procedure for purchasing recycled material made from Sammy machines (4) in the figure). This allows retired Sammy machines returned from pachinko halls to be reborn as new Sammy machines.

Since April 2024, we have been producing plastic parts partially made of recycled materials from our reuse scheme.

The Road to Realization of Recycled Material Circulation Scheme

Cross-departmental discussions resulted in the idea of a circulation scheme

Inouchi

Sammy produces around 200,000 machines a year, with a lifespan of at most three years and as short as a few months. As a Pachislot and Pachinko Machines manufacturer, we felt it would be a shame if the products we introduced were soon to fall into disuse. We also had a sense of challenge and responsibility to do something for sustainability as the Procurement Department.

I wondered if we could take our efforts a step further by collaborating with the Procurement Department’s efforts to procure recycled materials and the Reuse Planning Group’s efforts to reuse parts. Sammy has strong horizontal ties between departments, so if there is a theme we want to work on, we often work across departments.

When I talked to the Reuse Planning Group about it, we hit it off perfectly, as we both were aware of sustainability. During our discussions, we searched initiatives worldwide and found a circulation scheme. Until then, we had purchased recycled materials from outside, so creating a system in which the supply chain was not one-way was a new challenge. I decided to tackle it because I wanted to “try something new.”

Oyauchi

When I heard about the idea of the circulation scheme, I thought it was a good initiative because it would improve Sammy’s social credibility by being proactive in sustainability. Because I could visualize the scheme in my mind, I thought it would take shape immediately. Besides, I also wanted to try something new, so I decided to cooperate in any way I could as a member of the Reuse Planning Group.

Struggle not to Give up on Considering Quality and Cost as well as the Environment

In April 2023, a project team for the circulation scheme was formed by teaming up the Purchasing Department and the Reuse Planning Group. Here are some key points about the project.

Inouchi

As a Pachislot and Pachinko Machines manufacturer, we cannot release products of poor quality or unattractive quality because we are environmentally conscious. As a matter of course, we also put importance on quality. Besides, too much cost would make the business model unviable, so we needed to develop a system that would strike a good balance.

The following two initiatives are selected from the ones the teams put their trial and error efforts.

Initiative (1): Finding parts that can be used as raw materials for recycled materials

Oyauchi

For plastic to be used as a raw material for recycled materials, it must meet the quality standards required by the recycled material manufacturer. Since not all parts are available, finding out which parts could be used was difficult. We started by sending plastic parts of the retired Pachislot and Pachinko Machines returned from Pachinko halls to the recycled material manufacturer for their quality evaluation. After communicating many times with the manufacturer, we found parts that could meet their standards.

In addition, I brought used Pachislot and Pachinko Machines to the headquarters office and dismantled a number of them myself. The purpose was to find parts that could be easily used as raw materials for recycled materials by examining the weight and shape of the parts. It took me three to four months to select appropriate parts because I had other work to do.

Initiative (2): Preventing contamination by foreign substances

Oyauchi

To keep the costs as low as possible, we wanted to try transporting the materials efficiently from the dismantler to the recycled material manufacturer. First, we crushed plastics at a dismantler and then put the crushed pieces in a bag to transport. This method seemed to save space and carry crushed materials in large quantities. However, when we sent samples of the crushed parts to the recycled material manufacturer, they told us they could not be used. The reason was the crushed plastic contained foreign objects such as screws and metal fragments. If materials of different properties are contained even only 1% of the total, the quality of the recycled material cannot be maintained.

We discussed how we could remove screws and metal fragments from the crushed materials within the team and repeated experiments. We once purchased a metal detector and tried it out. However, detecting materials using a metal detector was time-consuming, and any foreign objects found must have been removed by hand. We gave up using it as it would have taken too many person-hours.

Finally, we decided to transport the plastic to the recycled materials manufacturer without crushing it, and thus selected parts shapes that could be carried as much as possible at one time. My experience in dismantling and verifying used Pachislot and Pachinko Machines helped me find a way.

After repeating the procedure of sending samples to the recycled material manufacturer for evaluation many times, we finally received an OK in January 2024. In April 2024, the first recycled materials produced by the circulation scheme were delivered to Sammy. After that, we began the process of producing parts and producing Pachislot and Pachinko Machines.

Recycled Material Circulation Scheme Completed after Overcoming Difficulties

Pachislot and Pachinko Machines produced under the circulation scheme were delivered to our customers

Pachislot and Pachinko Machines produced partly from recycled materials from the circulation scheme are already in operation. By December 2024, approximately 50,000 pachinko and 30,000 pachislot machines were shipped.

Inouchi

As we thoroughly verified the quality aspect, it has remained stable even after the actual introduction of the product to the market. All the hard work we have done so far has paid off.

Oyauchi

When shipping the product to the market, I hoped that nothing would go wrong, and at the same time, I was deeply moved. For me, in my third year with the company, this was the first project I had been in charge of from start to finish, so I was glad I could finish it.

Collaboration with many divisions centered on sustainability

Inouchi

I was glad to see our efforts bore fruit, as the Procurement Department has long been conscious of environmental considerations. The Reuse Planning Group was not the only group collaborating on this project. Development and quality assurance-related sections also had the same vision of working on sustainability in this way in the future. Their united efforts have further raised Sammy’s overall awareness of the issue.

Oyauchi

This project was made possible by the cooperation of various suppliers, including recycled material manufacturers and dismantlers, as well as in-house various departments. Many companies recognize the importance of sustainability but often do not know how to address it as individual companies or feel limited in the scope of what they can do. Therefore, from the beginning, we had a desire to work with our suppliers to promote this initiative. As society as a whole is being called upon to address sustainability, we at Sammy believe that what we can do is to take action and say, “Let’s work together on this,” and move forward together with our suppliers.

Sammy’s corporate culture allows the younger generation to take on challenges

Inouchi

At SEGA SAMMY Group, we are told to “make a good mistake early”. I believe these words symbolize the value of Sammy. At Sammy, even young employees in their first year of assignment can get involved in a project, and if they are enthusiastic, they are allowed to take on challenges. Besides, there are no barriers between departments. Because we can easily consult with other departments, new ideas, such as circulation schemes, are sometimes born from the discussion. We could proceed with the project even at the stand-talking level; it was easy to work on. I like this corporate culture.

Oyauchi

When I attended the company information session and the internship at Sammy as a student, I heard that the company allowed young employees to take on challenges. Still, I never expected to be entrusted with such an enormous task so soon after being assigned to it. I want those about to join SEGA SAMMY Group to know that even the younger generation can play an active role in the company.

Focusing not only on future "products" but also on the "environment”

As a manufacturer of Pachislot and Pachinko Machines, Sammy considers the environment in developing its products and operates its own recycling scheme for recycled materials to ensure sustainable product development. Employees, especially those of the future generation, worked together as a team and put effort while respecting the development policy of “Sammy… the wellspring of new ideas as an innovator in the industry” and the value of “Creativity is Genesis”×”Always Proactive, Always Pioneering”.

Sammy’s new slogan for its 50th anniversary 2025 is “Bet On! Sammy”. Our goal is to contribute to the sustainable development and revitalization of the amusement industry and society as a whole and to become a company trusted and needed by society.

SEGA SAMMY Group places importance not only on people but also on the environment. This project provided an example of how Pachislot and Pachinko Machines manufacturers can also be environmentally conscious by implementing a recycled material circulation scheme for Pachislot and Pachinko Machines. The entire group will continue its commitment to the environment and sustainability.